Chapter 1

Preparation of DNA

printing plates

Task A: PCR Cocktail

Preparation

Objective:

Preparation

of mix to be added to yeast ORF specific primers for amplification of Saccharomyces cerevisiae genome ORFs

(~65 96-well plates)

Procedure:

- Prepare cocktail of PCR

buffer, magnesium chloride, dNTPs, Taq, etc. for four plates (=40 mL) in a

50 mL conical tube as follows:

|

|

One rxn |

Four

96-well plates |

|

RESGEN

ORF SPECIFIC PRIMERS: |

|

|

|

Forward

primer (20 uM) |

5

uL |

- |

|

Reverse

primer (20 uM) |

5

uL |

- |

|

10X

PCR buffer |

10

uL |

4000 uL |

|

MgCl2

(1 M) |

.05

uL |

20 uL |

|

100X

dNTPs (25 mM each) |

1

uL |

400 uL |

|

Yeast

genomic DNA (0.2 ug/uL) |

0.2

uL |

80 uL |

|

ddH2O

|

77.95

uL |

31.36 ml |

|

AmpliTaq

(5 U/uL) |

0.35

uL |

140 uL |

|

Total

volume |

100

uL |

90 uL aliquots |

- Mix well by inverting

tube

- Store at –20 C if not

to be used in less than 24 hrs (4 C if within 24 hrs)

Task B: PCR amplification of

yeast ORFs

Objective:

Addition

of premade PCR cocktail mix to yeast ORF specific primers, followed by thermal

cycling for amplification of yeast genome ORFs (~65 96-well plates).

Procedure:

- Pour cocktail into

disposable trough. Using

12-channel pipetman dispense 88 uL of cocktail to the pre-aliquoted

primers. Carefully mix by pipeting

up and down 3 times

- Place rubber mat over

PCR plate. Spin plate at 500 rpm

in table-top centrifuge, to remove air bubbles from mixture (very

important)

- Place plates in tetrad

PCR machine. Maintain same

orientation for all plates (eg, A1-12 always closest to back hinge) for

tracking heat block geographic problems.

Record plate/PCR block/time.

Closing lid of tetrad PCR machine: Design of tetrad lids promotes evaporation during PCR reaction, increasing failure rate. To close lid properly, tighten until lid lifts up off the body of the PCR machine, then loosen lid JUST until it again touches the body of the PCR machine. - Run program with the

following steps:

·

pre-melting 92ºC (1’)

melting 92ºC

(30")

annealing 56ºC

(45")

synthesis 72ºC

(3'30")

# cycles 36

·

soak

at 4-11ºC (hold forever)

- PCR reaction takes

approximately 3.5 hours

- Remove from PCR machine

- Store at 4 C if next

step is less than 24 hours away (-20ºC if need more time)

- Expect ~92-95% success

rate after first pass

- Following

characterization of success rate by running gels (see below),

re-amplify

failures.

Task C: Preparing agarose

gels for electrophoresis

Objective:

To

cast gels for running out products of each amplification reaction.

Procedure:

1.

Prepare

800 ml of 1% agarose in 1X TAE (200

ml/gel tray times 4 trays, each for one 96-well plate)

2.

Cook

in microwave or on stirring heat block until boiling.

3.

Allow

to cool to 55-60ºC

4.

Prepare

4 trays by taping ends well. Place four combs of 26 wells each into gel.

5.

Adjust

molten TAE agarose to 0.5 mg/mL ethidium bromide after having cooled to

~55-60ºC to avoid excess vaporization.

6.

Pour

200 ml of cooled molten agarose into each prepared tray (above 65ºC may warp

tray)

7.

Allow

to polymerize 20-30 minutes

8.

Store

in 1X TAE buffer containing 0.5 mg/mL ethidium bromide

Task D: Verification of PCR

success by gel electrophoresis

Objective

To

verify success of the PCR and also roughly size the products to verify

identity. High resolution on the gels

for exact sizing is not required, as this step is largely for quality control.

Procedure:

|

Agarose

gel: |

1%

agarose, 1X TAE, 0.5 mg/mL ethidium bromide |

|

Running Buffer: |

1X

TAE, 0.5 mg/mL ethidium bromide |

|

Loading dye (6X): |

15%

Ficoll-400, 0.25% xylene cyanol FF, 0.25% bromophenol blue |

|

DNA size ladder: |

4

mL 1X TE buffer, 1 mL 1kb ladder, 1 mL 6X loading dye |

|

1 |

Start

with 3 uL of PCR reactions in PCR plates, after remainder is transferred to

U-bottom plates (see next section). (can mix PCR + dye directly on parafilm

or in a fresh plate) |

|

2 |

Add

1 uL 6X loading dye to PCR reactions in PCR plates. |

|

3 |

Load

6 uL DNA size ladder in lane #1 of each row. |

|

4 |

Using

a 12-channel pipettor, load samples A1-A12 into alternating lanes 2, 4,...,

24. |

|

5 |

Load

samples B1-B12 into alternating lanes 3, 5,..., 25. |

|

6 |

Repeat

this procedure for the remaining samples, such that two sequential rows of

PCR reactions are loaded into a single row of wells in alternating lanes. |

|

7 |

Run

at 70-80V until the first dye band (XC FF) is halfway to the next row of

wells. |

|

8 |

Take

a high (~1") and low (~6/30") exposure photographs. Compare

to predicted ORF sizes and for the presence of significant doublets. |

|

9 |

Repeat

PCR rxns for failed ORFs. NOTE: For

2nd PCR attempt, sort failures by gene size, doublets, etc., and modify

reaction conditions accordingly. For

genes that still give PCR failures, design new primers, e.g. to amplify

subregions of genes. |

Notes:

- Loading gels: easiest to mix and load 24 wells at a

time. Aliquot 24 spots of 1uL gel

dye, add 3uL of PCR reaction, mix by pipeting, and then directly load 12

wells of the gel. Repeat this for

another 12 wells (i.e. two rows from the 96 well plate loaded into one row

of wells on the gel). Apply low

voltage while preparing other samples to prevent diffusion of the DNA

during loading.

- Running gels:

·

Do

not run short products (<300 bp) off the gel. To ensure this, run until blue dye is 2/3 down the gel.

·

b. During gel running, be sure gel is centered

in gel box and resting within the plastic frame: if the gel floats off the frame toward the cathode the DNA will

run out the BOTTOM of the gel leading to false negatives.

Tasks E-L: DNA Cleanup

Task E: Transfer of PCR products to precipitation

plates

Task F: Addition of isopropanol to PCR products

Task G: Precipitation of DNA by centrifugation

Task H: Aspirating isopropanol

supernatants

Task I: Addition of ethanol to PCR

products

Task J: Precipitation/wash of DNA by

Centrifugation

Task K: Aspirating ethanol

supernatants

Task L: Resuspension of dried ORF DNA

Objective:

To cleanup PCR products in preparing spottable DNA for arraying.

Procedure:

Task

|

Step

|

|

|

E |

1. |

[This

step is optional and we will not be performing it in this course. Instead, we will precipitate the PCR

products directly in the PCR plates.] Transfer

PCR reactions to 96-well U-bottom tissue culture plates (Costar #3790). |

|

|

|

If

gels have not been run, transfer 3 uL back to PCR plates for check gels (see

above). |

|

F |

3. |

Add

1/10 vol. 3M sodium acetate (pH 5.2) (10 ul to a 100 ul PCR reaction). Then add 1 volume (100 ul) isopropanol and

pipet up and down 3 times. Change

pipet tips between rows. |

|

|

|

Store

at -20ºC for a few hours to overnight (this is optional.) |

|

G |

4. |

Centrifuge

the plates in Sorvall at 3500 rpm (RC3B rotor) for 1 hr. If precipitating in PCR plates, use plastic

holders designed for PCR plates in order to support them during the spin. |

|

H |

5. |

Invert

plate over sink in order to remove supernatant. Alternatively, remove supernatant with 12-channel aspirator

(Wheaton/PGC Scientific #851388) |

|

I |

6. |

Add

100 uL of ice-cold 70% ethanol and centrifuge again for 30 min. |

|

|

7. |

Dry

the pellets in speed-vac for 10 min (if available). |

|

J |

8. |

Resuspend

DNA in 100 uL dH2O overnight. |

|

|

9. |

Transfer

in 10 uL aliquots to 384-well plates (Corning Costar #6502) to make 10 duplicate

print plate sets. |

|

K |

10. |

Dry

down print plate sets in speed vac (if available). |

|

|

|

Tightly

seal plates with aluminum foil (R.S. Hughes #425-3) for long-term storage at

room temperature. |

|

L |

11. |

Before

use, resuspend one print set in 4-5 uL 3XSSC and allow to hydrate overnight. |

|

|

|

|

|

|

|

|

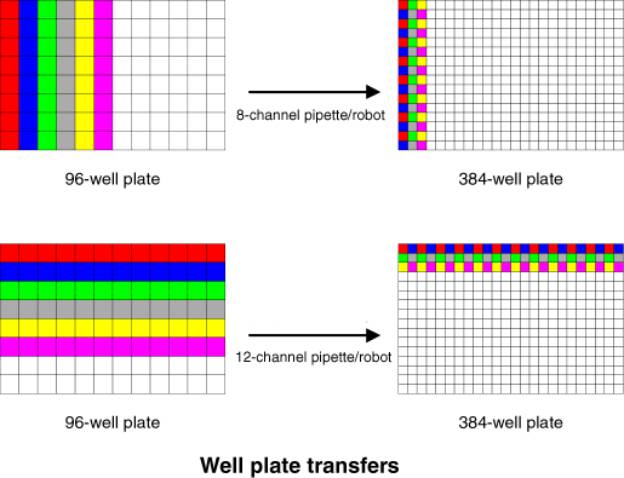

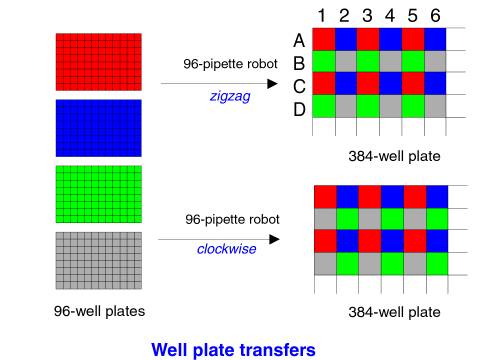

Task M: Rearray into

384-well plates

Objective:

To reformat spottable PCR products from 96-well to 384-well plates, in preparation for arraying (converting from 9-mm to 4.5-mm well spacing).

Procedure:

This

rearraying scheme ignores the most common 96 to 384 reformatting schemes,

namely ones which use robots with 96 tips (eg, Beckman Multimek, Robbins Hydra,

Tecan, Hamilton, etc.). These robots, fill a 384-well plate using four

interlaced 96-well registers corresponding to the 4 constituent 96-well plates.

Most

commonly, this is done in one of two ways:

- "ZIGZAG",

Beckman Multimek's Default: 4 registers anchored at the top left (96-well

position A1) fill 384-well plate as follows: top left for register 1 is A1,

register 2 is A2, register 3 is B1, and register 4 is B2.

- "Clockwise",

Robbins Hydra's default: again, 4 registers anchored at the top left

(96-well position A1) fill 384-well plate as follows: top left for

register 1 is A1, register 2 is A2, register 3 is B2, and register 4 is

B1.

Other

schemes also exist:

Chapter

2

Preparing to print

Poly-L-lysine

coating of glass slides for microarraying

Glass slides can be treated with a variety of

coatings for attaching DNA to the surface, but in our experience, poly-L-lysine

coating is the most convenient and best performing method of attachment. Although it's possible to buy lysine coated

slides commercially, most of them are not as good as those you can make on your

own with adequate care. Many commercial

slides we have seen have dirt on the surface or uneven coatings of lysine.

The coating procedure consists of first cleaning

the slides thoroughly with a basic ethanol solution and rinsing, followed by

immersing them in a buffered solution of lysine. The slides are then rinsed briefly and spun dry to achieve an

even coating.

|

Materials |

Quantity |

Ordering information |

|

Glass microscope slides |

60 |

Gold Seal #3010 |

|

Slide rack with handle |

2 |

Shandon Lipshaw #121 (800-245-6212) Each rack holds 30

slides |

|

Slide chamber |

6 |

Shandon Lipshaw #121 |

|

Double distilled water |

~5 L |

|

|

NaOH |

70 g |

|

|

95% Ethanol |

420 mL |

|

|

Poly-L-lysine |

70 mL |

Sigma # P 8920 |

|

Tissue culture PBS |

70 mL |

|

|

Vacuum oven (45C) |

|

|

|

Slide box (plastic only) |

1 |

VWR #48443-806 |

Notes

Wear powder free gloves whenever you handle

slides in this protocol.

Directions

1. Rinse

the glass chambers with the metal slide racks thoroughly with distilled water

and get rid of most of the water by shaking & air drying. Place 30 slides in each slide rack.

2. Prepare

cleaning solution: Dissolve completely

70 g NaOH in 280 mL ddH2O. Add 420 mL

95% ethanol slowly and stir until completely mixed. The total volume is 700 mL

(= 2 X 350 mL). If solution remains cloudy, add double distilled H2O until

clear.

3.

Pour

cleaning solution into 2 empty slide chambers.

Use the wire handle to dunk the rack of slides into the solution, plunge

it up and down briefly and cover chambers with glass lids. Shake on an orbital

shaker for 2 hr. Once slides are clean, they should be exposed to air as little

as possible. Dust particles will interfere with coating and printing. You should also ensure that PBS solution is

made up at this point. (1 litre PBS has 8 g Sodium chloride, 0.2 g potassium

chloride, 1.44 g Sodium phosphate, dibasic, anhydrous and 0.24 g potassium

phosphate, monobasic)

4. Quickly

transfer racks to fresh chambers filled with double distilled H2O. While

transferring, tilt the rack to drain as much of the cleaning solution as

possible. Rinse vigorously by plunging racks up and down in the fresh

water. Repeat rinses at least 4 times

with fresh double distilled H2O each time. It is critical to remove all traces

of NaOH-ethanol. The slides remain in

the final rinse water till the next step, which is the lysine coating.

5. Prepare

poly-L-lysine solution: 70 mL

poly-L-lysine + 70 mL tissue culture PBS + 560 mL water. Use a plastic

graduated cylinder and beaker. Pour

this lysine solution into two clean slide chambers.

6. Transfer

the racks of slides from the rinse water to the chamber with poly-L-lysine

solution and shake for 1 hr on the orbital shaker.

7. Transfer

rack to fresh chamber filled with double distilled H2O. Plunge up and down to

rinse for about 1 minute.

8. Place

slides on microtiter plate carriers (place paper towels below rack to absorb

liquid). It is best to do this step (transfer from water to centrifuge carrier)

right at the centrifuge to avoid exposing the wet slides to air for any length

of time. Centrifuge for 5 min. at 500

rpm. This step ensures even coating and

drying of the slides. Transfer the

slide racks to dry empty chambers with covers for transport to vacuum oven.

9. Dry

slides in the racks (with cover off chamber) in 45 C vacuum oven for 10 min.

(Vacuum is optional.)

10.

Transfer

slides from the racks to a clean slide box.

The slides should look perfectly clean when inspected against the light.

Store slides in closed slide box (plastic only, without rubber mat bottom) till

they are ready for use in the printing process.

10.

Normally,

the surface of lysine coated slides is not very hydrophobic immediately after

this process, but becomes increasingly hydrophobic with storage. A hydrophobic surface helps ensure that

spots don't run together while printing at high densities. This may not be a problem with fine printing

tips and adequate spot-to-spot spacing, so the coated slides may be ready for

use in a day or two. After they age a

few days, (up to a week) they are probably optimal. The hydrophobicity can be tested by observing how a drop of water

beads off the surface (compare this to a just coated or un-coated slide). However, coated slides that have been

sitting around for long periods of time (few weeks) are usually too old to be

used. They often show opaque patches

when held to the light and these result in high background hybridization from

the fluorescent probe. It's useful to

test print, hybridize and scan sample slides to determine slide batch

quality. Inspect every slide before

placing it on the arrayer to ensure you don't use one that has obvious problems

like dirt, uneven coating or opaque patches.

Organization

(Group of 4 students)

Common

task-make PBS for everyone

|

Student

1 & 2 |

Wash

chambers, place slides in rack |

15

minutes |

|

Student

3 & 4 |

Make

cleaning solution |

|

|

|

Cleaning |

2

hours |

|

Students

1& 2 |

Make

poly-l-lysine solution |

|

|

Students

3 & 4 |

Rinse

4x, 1 rack each |

15

minutes |

|

All |

Poly-L-lysine |

1

hour |

|

Students

2 & 3 |

Rinse,

dry & store |

15

minutes |

Post-Processing of printed microarrays

After printing microarrays on

poly-L-lysine coated glass slides, the slides need to be processed before they

can be used for hybridization. Most

importantly, the remainder of the lysine coated surface needs to be blocked to

prevent non-specific attachment of the fluorescently labelled probe DNA to the

free amine groups. Blocking is achieved

by treating the surface with succinic anhydride (in an organic solvent), which

forms an amide bond with the free amines.

The processing step also rehydrates the array to make individual spots

more even and probably also denatures the DNA to some extent.

Materials Needed

|

Materials for 30 arrays |

Quantity |

Order info |

|

Humid chamber |

1 |

Sigma #H 6644 |

|

Diamond scriber |

1 |

VWR #52865-005 |

|

Slide rack with handle |

1 |

Shandon Lipshaw #121 |

|

Slide chamber |

2 |

Shandon Lipshaw #121 |

|

Succinic anhydride |

6 g |

Aldrich #23,969-0 |

|

1-Methyl-2-pyrrolidinone |

325 mL |

Aldrich #32,863-4 |

Inverted heat block (90-100 C)

Sodium borate (1M, pH 8), 15

mL Make this by dissolving boric acid

in water and adjust pH with NaOH

double distilled H2O ~1 L

2 L glass beaker

95% ethanol 350 mL

Notes

Wear powder-free gloves for the entire procedure.

Directions

1. Mark

the array boundaries: The spots on an array will become invisible after

post-processing as the salt gets washed away.

Since you need to know where to pipette the probe on, you have to mark

boundaries of the array. The best way

is to etch a couple of lines just outside the top and bottom of the array, on

the back of the slide using a diamond scriber.

If the arrays are not labelled, now is the time to do it. Labelling can be done with peel-off labels

or with the diamond scribe (see array printing). You need to be able to orient the array properly using the

labels.

2. Fill

the bottom of humid chamber with 100 ml 1X SSC. Place arrays face down over the 1X SSC in the chamber and cover

with lid. Spots will take up moisture

and swell. Re-hydrate until array spots

glisten, approximately 5-15 minutes.

This is best monitored by looking at the spots with a magnifying

glass. Allow the spots to swell

slightly but not run into each other.

Using a slightly warm solution (35-40 C) is one way to speed things up.

3. Quickly

transfer slides with their array side up, one by one from the humid chamber to

the smooth surface of an inverted heating block at 90-100 C. Snap-dry each

array for a few (3-5) seconds. You can

usually see a ‘wave’ of dryness sweeping across the array as the spots are

snap-dried.

4. Place

arrays in metal slide rack with wire handle. Keep it close to a clean, empty

slide chamber on an orbital shaker. Be

sure the rack is bent slightly inwards in the middle, or else the slides may

run into each other while shaking.

5. Prepare

blocking solution: Have three 350 ml glass chambers with lids available, as

well as a 2 L glass beaker or large round pyrex dish with double distilled

H2O to a height of about 3 in., just enough to cover the rack of slides. The water should be heated in the microwave

or on a heating plate to close to boiling.

At this time, prepare the 15 ml sodium borate in a 50 ml conical tube.

6. Dissolve

6 g succinic anhydride in approx. 335 mL 1-methyl-2-pyrrolidinone. The most efficient way to do this is to have

a clean 500 ml graduated glass beaker with a stir bar on a stir plate. Weigh the succinic anhydride and drop it

into the beaker. Pour

1-methyl-2-pyrrolidinone from the stock bottle into the beaker till it is

approximately 335 ml and turn on the stirrer.

7. Immediately

after the last flake of the succinic anhydride dissolves (about a minute), add

the 15 mL sodium borate into the still stirring solution.

8. Immediately

after sodium borate solution mixes in, pour the solution into empty slide

chamber on the orbital shaker. Plunge

slide rack rapidly and evenly in solution.

Vigorously shake up and down for a few seconds, making sure slides never

leave solution.

9. Shake

on orbital shaker for 10-15 min. Ensure that the water in pyrex dish or glass

beaker is maintained at a point just before boiling (95 C).

10. Transfer

the rack of slides from the blocking solution to the 95C water. Gently plunge

slide rack in hot water for 2 min.

11. Transfer

the rack of slides to a slide chamber with 95% ethanol. Plunge slide rack a few times in the

ethanol.

12. Take

the chamber with slides in ethanol to the centrifuge and transfer the rack to

the carriers. Load slides quickly and

evenly onto the carriers to avoid streaking.

Centrifuge slides and rack for 5 min. @ 500 rpm.

13. Transfer

arrays to a clean slide box. They are

ready for use immediately. Processed

arrays are good for many weeks.

Organization (Group of 4

students)

|

All (in turn) |

Etch slides |

10 minutes |

|

All (in turn) |

Rehydrate and snap dry |

20 minutes |

|

Students 1& 2 |

Blocking |

20 minutes |

|

Students 3 & 4 |

Transfer to water, ethanol

and dry, cleanup |

10 minutes |

PRINTING MICROARRAYS

A microarray printing run of more than a hundred

microarrays with many thousands of elements each is always a fun and rewarding

activity, but without the right attitude, it can become a chore that you

dread. A typical print run takes about

a day of non-stop printing depending on the number of printing tips and elements

to be printed. Someone knowledgeable

needs to be near the machine constantly to make sure everything is going

smoothly. Before you begin the run, you

need the following:

Notes

1. DNA

to be printed, aliquoted in printing plates:

It’s best to have this in 384-well plates. The best printing plates are Genetix 384-well plates (see DNA

prep and precipitation section for details).

For printing, the DNA needs to be in about 4 ul of 3X SSC. Obviously, you should know how the DNA was

aliquoted. The best method of storing

print plates is to dry them down. If

DNA in water was dried down, you need to add 3X SSC and if it was dried down in

3X SSC, you will be adding water. This

might seem like an obvious point, but when there’s a production pipeline going with

many people doing different steps, it’s easy to lose track! If dried down DNA needs to be resuspended,

add the water or SSC a few hours before beginning the print run. After it is resuspended, keep the plate

tightly sealed to minimize evaporative losses.

2. Familiarity

with the ArrayMaker software: You

should know how to do alignments and what the different parameters in the test

print and print window mean.

3. Glass

slides: You need plenty (~150) of coated glass slides from batches that have

been tested with test prints and hybridizations. See poly-L-lysine coating and test print sections.

4. Printing

tips: You should have many spares in addition to the 16 or 32 that you are

planning to print with. Obviously,

these should all be in good condition.

5. Other

materials: 3X SSC, double distilled water, test print DNA (100 ng/ul sheared

salmon sperm DNA in 3X SSC), ¼’ wide labelling tape, magnifying glass. Also useful is a dissecting microscope to

inspect printing tips, and a camera attached to a monitor that will let you

observe the arrays being printed.

Directions

Details for some of

the following steps are covered in the software section:

Turn on the main power and computer, run ArrayMaker and home

the stages

See the Mguide and

software section for details.

Align

all positions

It is necessary to make sure that all the

positions are correctly aligned at the start of every print run. Although none of the positions might have

changed, there’s always the possibility that someone had last printed with a

weird configuration of tips in a 32-tip holder and aligned that to the dry

station and print plate, or used a slightly different print plate. If you are not absolutely sure that all of

the positions are perfect, align everything.

It’s a good idea to make sure anyway. Clicking on the Align button on

the main window takes you to the align window.

In the Align window, clicking on the “Reset Z” button resets all the

vertical positions to the ready position, which is safely above everything. You

can then click on the buttons for the various positions and carry out

alignments. See the software section

for details on alignment. The tips in

the rinse station (sonicator) should be aligned with only the slot immersed in

the liquid. Remember to set and save

before exiting this window. If you are

printing with less than 32-tips (and using a 32-tip holder and dry station),

cover the unused holes in the dry station with a piece of tape.

Printing

tips

The quality of microarrays you print depends a

lot on the printing tips (the DNA in the printing plates is another major

factor). The current generation

printing tips pick up ~ 0.5 ml of solution and deposit a few nl with

every tap on the glass surface. A good

printing tip should be able to print 100-200 spots before it needs to be loaded

again. A good set of 16 or 32 tips

should produce uniformly sized, distinct, well spaced spots across the entire

array. Before beginning, inspect the

tips carefully for obvious imperfections under a dissecting microscope. You can observe how well a tip picks up

liquid by just touching the tip to the surface of a 3X SSC solution. With a good tip, you should see the solution

wicking up in the slot in the center of the tip. Make sure the outside is free of any salt or corrosive build-up,

especially at the retaining clip or inside the slot. Once the tips are in the holder and the top is on, use forceps or

needle nose pliers to make sure all the tips slide up smoothly and that the

spring pushes them back down when released.

You might need to clean the tip-holder holes of any build up. Gentle sanding of the outside of the tip

(where it rubs against the tip-holder) might also be called for

occasionally. Use a fine grade

sandpaper for this. If the shaft of the

printing tip is slightly bent, it affects the smooth up and down movement and

also alters the register of the different sectors of the test print array. If this is the case, replace the tip to get

a set that is well matched and evenly spaced.

Tips should be cleaned after every print run by sonicating in warm water

and rinsing with ethanol. Handle tips

with great care. Their points should

never hit anything hard except the slides while printing. Putting them in 200 ul pipette tips is a

convenient way to store them.

Test

prints

It is important to do test prints with the tips

that will be used for the print run, immediately before beginning the run. Tips that have performed well in the past

may gradually deteriorate with improper cleaning and other abuse. Load a sample print plate that is identical

to the real print plates with 4-5 ml test print

DNA in the top left 16 or 32 wells (beginning at A1) and use this for test

printing on slides from the same batch that will be printed on. The test print parameters (spacing and

number of spots across) should match what the real array is going to have. This can be calculated depending on how many

elements total you need to print (see software section for details). Tape down

a glass slide in position 1 on the platter (closest to the plate holder) for test

printing. If printing with 16 or 32 tips,

it’s very convenient to simply print 24 spots across in each quad. This way, one row of spots on the array

corresponds to 1 or 2 384-well plates and makes it easier to localize

imperfections to specific print plates.

However, this will limit the total number of spots you can print. You can set the tips to load multiple times,

which allows you to print thousands of spots on the same test-print slide. You can use the same wash and dry parameters

as for the actual run or shorten them slightly.

The liquid in the sonicator for cleaning the

tips can be either water or SSC (0.5 X or 1 X). Using SSC leads to somewhat better ‘priming’ of the tips and they

can then print more spots before running dry, but depending on the DNA in the

print plates, it could also lead to spots that tend to spread. You should do a test print run using a spare

sample plate of the actual DNA that will be printed to see how different wash

solutions affect the spot quality. Do

test prints from different load positions on the 384-well plate to check the

plate alignment, and on different slide positions on the platter to check the

slide height adjustment on the platter.

Use of the plate positioner is strongly recommended.

Printing the real microarray

Once you have a

set of printing tips working perfectly on the test print, start the array print

run immediately. Set the print

parameters in the Print Array window.

To prevent carryover on the tips, it is necessary to do at least 3

cycles of cleaning, with 5-6 sec sonication and 8 sec dry times. A few other things to note: You of course know how many printing plates

total you have, but set the spacing so that you have room for more. Printing a plate of controls is useful. The

control plate can include l DNA, salmon sperm DNA, poly dA, Cot1 or

other low complexity repeat containing DNA, genomic DNA, 3X SSC, clones

corresponding to doped in controls, dilutions of fluorescently labelled cDNAs,

etc. as positive and negative controls. You should also try to leave room for

re-printing a few plates should there be a problem with some of them.

When all the parameters are properly set, you

are ready to begin. Spray off the dust

and glass shards on the platter and wipe the surface with a moist kimwipe. Place your slides (wearing powder-free

gloves) on the platter, making sure they are aligned straight and lying

flat. If printing less than 137 slides

(a no-no!) you should fill the platter in the order they will get printed. Use the ¼’ tape to tape down all slides

along the edge. Don’t put the tape on

top of the dowel pins on the platter.

Use pieces of tape to tape across columns. Taping securely is important as you don’t want your slides moving

around during the print run. Place the

dust cover on as soon as you are done taping the slides down.

Spin down every print plate just before putting

it into the plate holder. You want to

ensure there’s no liquid on the sides of the wells. Be careful when taking off the seal. Make sure the plate is placed in the proper orientation in the

holder. Again, the plate positioner helps.

You will have a spreadsheet listing the contents of each well in the

printing plates. The order and orientation

on the slide platter determines where each DNA is going to end up on the array,

and only you can keep track of this.

It’s very useful to keep a log at the arrayer where the orientation and

plate number of every plate can be recorded for each print run. When everything

is ready, drop the first plate in and click the start button!

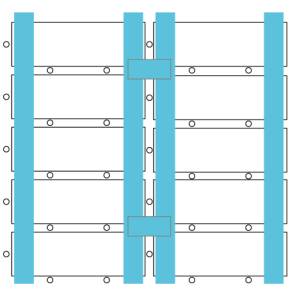

Taping diagram

Monitoring

the run

Close monitoring is essential throughout the

run. A live CCD camera with a macro

lens or attached to a microscope, and hooked to a monitor, makes things a lot

easier. You basically need to ensure

that all the tips are printing well on all the slides. It’s sometimes necessary to use the reload

feature if some tips are unable to print till the end of the platter. Often, the first few slides have larger

spots; this is normal. If they begin

running in to each other a lot in the beginning of the platter, you might want

to turn on the blot pad feature. Check

the level of liquid in the sonicator every few plates. In case of printing problems, you can stop

the run after making note of the plate and load number. Then remove the first slide, put in a fresh

one, and do a few test prints (with test print DNA) and diagnose the

problem. Is a single tip printing large

spots? The tip could be blunted or the

slot could be misshapen or something could be clogging the tip. Look under the scope and try cleaning it

gently. Has a tip stopped printing?

Make sure it continues to slide smoothly up and down in the holder and that

it’s touching the slide on the test print.

Are all the tips misbehaving? It

could be due to salt or corrosive build up on the tips. You can move the stage to the right to

immerse the tips briefly in warm water, and then inspect them. After this make sure the tip holder bottom

holes are dry and free of crud. Are

some isolated slides on the platter missing spots? Maybe the Z-height has not been corrected for those

positions.

Remember, many

seemingly disastrous runs are salvageable.

If a bad tip problem crops up in the middle of a plate, and you lose a

lot of spots on the array, you can print that plate again at the end of the run

if you’ve managed to fix the problem. It’s usually not worth ‘filling in holes’

on the array as you have to keep careful track of which slides are missing

which spots and so on. It’s far easier

to reprint an entire plate at the end, which is why it’s good to leave room for

a few extra plates. When you stop and

start up again, make sure that the printing starts exactly where you stopped by

entering in the appropriate values for the current plate, slide and load in the

Print window. Stopping a print run to

catch some sleep at night is unseemly.

Tag team instead and carry on the through the night. You’ll get the arrays faster that way.

Ending the run

Once all plates are

printed, you can begin another run immediately with the same print plates. If you are not up to that (or if you don’t

have enough fresh slides), it's best to dry down the plates in the speedvac and

seal them for the next run. The first thing

though, is to remove the slides and clean the tips. Carefully peel the tape off the slides without touching the

surface of the arrays. It helps to have

an extra person to hold down one edge of the slides while the other peels tape

from the other end. Alternatively you

can use the edge of a long strip of metal like a ruler to hold down the slides

when the tape is pulled off. Some

people like to label the slides at this point, especially if using stick on

labels. Put the printing tips in fresh

warm water in the sonicator and clean for a few minutes. Inspect tips for any corrosive or salt crud

inside the slot. Cleaning with ethanol

may also help. Store tips dry.

Chapter 3

Microarray Hybridizations

Harvesting Cells from Liquid

Culture

This is a very simple protocol for collecting yeast cells from

liquid culture, basically just chilling, spinning, and freezing.

Reagents

Collection tubes

Pre-chilled centrifuge

Liquid nitrogen

Ice

Directions

(1) Fill a collection

tube with ice, so that there is as much ice in the tube as there will be

sample.

(2) Pour the sample

into the tube. Mix by shaking.

(3) Pellet the cells

by centrifugation.

(4) Decant, and freeze

pellet by submersion in liquid nitrogen.

(5)

Store at –80 C.

Notes

There are many different variations on this protocol. The key elements are to stop gene expression

quickly, by cooling or freezing. The

method also works well if a fast spin (<3 min) is used and the samples

remain at their experimental temperature.

Generally longer spins with ice to chill the cells are the easiest way

to go.

RNA

Preparation

RNA preparation is one of the most important steps in expression studies. RNA that is undegraded and free from contaminants will work well when labeled cDNA is generated later. We have found that acid phenol methods are robust and easy. The general goal is to quickly take frozen cells and add hot phenol which will break open the cell wall and separating nucleic acids from unwanted cellular components. It is generally helpful to perform the extractions multiple times to ensure that high quality RNA is prepared.

Reagents

Water

saturated phenol Solid phenol,

melted and saturated with water

Sodium

acetate buffer 50

mM sodium acetate, 10 mM EDTA pH 5.0

10%

SDS

chloroform

95%

ethanol

70%

ethanol

Isopropanol

Water

bath at 65 C

Vortexer

3M

sodium acetate pH 5.3

de-ionized

water

Directions

(1) Fill phenol resistant tubes with 10ml

phenol.

(2) Add 9ml sodium acetate buffer and 1ml

10% SDS.

(3) Immerse in 65 C bath, until heated.

(4) Warm frozen cell pellets to ~ 0 C.

(5) Add 1ml phenol/buffer mixture to each cell pellet, returning

each mixture to the larger tube and then vortex for 10s.

(6) Heat at 65 C for 7-15 min, vortexing for

10s every 1-2 min.

(7) Centrifuge to separate phases (about 10

min, 3,000 g).

(8) Remove aqueous to second tube containing

10ml phenol.

(9) Vortex briefly, separate phases again.

(10) Remove aqueous to third tube containing

5ml phenol, 5ml chloroform.

(11) Vortex briefly, separate phases again (15

min, 3,000g).

(12) Transfer aqueous to a fourth tube.

(13) Add 1/10th volume sodium

acetate, and either one volume of isopropanol, or two volumes of ethanol.

(14) Centrifuge to precipitate RNA (~30 min,

3,000g).

(15) Wash RNA pellet with 70% ethanol.

(16) Dry pellet at room temperature.

(17)

Re-suspend

RNA in water. Store at –80 C.

Notes

Again there are many variations in protocols. Increased yield can be obtained by lengthening the hot phenol step, or by pelleting the cell debris and reextracting it with more hot phenol. Phase-lock tubes (5’ -> 3’ inc) are a useful way to make the separations easier (and reduce them). It is relatively important to quickly get the frozen cells into the phenol/buffer mixture to prevent gene expression changes.

Amino-allyl

Labeling of cDNA by Reverse Transcription

The amino-allyl based labeling procedure is far more cost effective, and yields fluorescent probes that are much brighter than can be obtained by direct incorporation. There protocol is somewhat longer, but the efort is worthwhile.

I.

RT Reaction

Oligo

dT/Random Prime RNA:

|

|

Concentration |

uL |

|

Oligo dT:pdN6 |

5ug/uL |

1 |

|

Total Vol. of RNA |

|

14.5 |

Incubate

RNA and oligo dT at 70° C for 10 min.

Chill

on ice 10 min.

|

1x dNTPS: |

|

|

500uM each dA, dC, dG |

|

|

200uM aadUTP 300uM dTTP |

|

|

50x recipe: FOR 2:3 |

|

|

10uL each dA,dG,dC |

|

|

4uL aa-dUTP |

|

|

6uL dT |

|

cDNA

synthesis

|

|

Concentration |

uL |

10.5 |

|

5x buffer |

|

6 |

63 |

|

50x aa dUTP/dNTPs |

|

0.6 |

6.3 |

|

DTT |

0.1M |

3 |

31.5 |

|

SuperScript II |

|

1.9 |

19.95 |

|

Water |

|

3 |

31.5 |

|

|

|

14.5 |

14.5 |

|

42 degrees for 2

hours |

|

Aliquots |

|

II. Hydrolysis

Add: 10ul 1N NaOH

10ul

.5M EDTA

Incubate:

15 min. at 65°C.

Neutralize: 25ul 1M Tris

pH 7.4

III. Cleanup

To continue with the

amino-allyl dye coupling procedure all Tris must be removed from the reaction

to prevent the monofunctional NHS-ester Cye dyes from coupling to free amine

groups in solution.

Fill one Microcon 30

concentrator with 450 ul water.

Add neutralized reaction.

Spin at 12K for 8 minutes.

Dump flo-thru.

Repeat process 2X,

refilling original filter.

Elute.

Dry eluate in speed vac.

IV. Coupling

Resuspend cDNA pellet in

4.5ul water.

Resuspend monofunctional NHS-ester

Cy3 or Cy5 dye:

If using aliquot,

resuspend in 4.5ul .1M NaBicarbonate Buffer pH 9.0

If using fresh tube of

Cy3/Cy5, resuspend entire tube in 72ul water.

Aliquot 4.5ul x 16 tubes

and dry in speed vac.

Resuspend aliquot in 4.5ul

.1M NaBicarbonate Buffer pH 9.0 as above.

Mix dye and cDNA.

Let incubate 1 hour at RT

in dark.

V.

Quenching and Cleanup

Before combining Cy3 and

Cy5 samples for hybridizations, the reactions much be quenched to prevent cross-coupling.

Add 4.5ul 4M hydroxylamine.

Let reaction incubate 15 min. at RT in dark.

To remove

unicorporated/quenched cye dyes proceed with Qia-quick PCR purification kit.

Combine Cy3 and Cy5

reactions.

Add 70ul water.

Add 500ul Buffer PB.

Apply to Qia-quick column and

spin at 13,000 rpm in for 30-60 sec.

Aspirate off flo-thru.

Add 750ul Buffer PE and spin

30-60 sec.

Aspirate off flo-thru and

repeat.

Aspirate flo-thru and spin for 1 min. at high speed to dry

column.

Transfer to fresh epp. tube

Add 30ul Buffer EB to center

of filter and let sit 1 min. at RT.

Spin at 13,000 rpm for 1 min.

Repeat elution step again.

VI. Hyb. Prep.

Dry

down Qia-quick eluate in speed vac.

Bring volume to 18

ul with water.

Add: 3.6ul 20X SSC

1.8ul polyA(10mg/ml)

Optional: filter in Millipore 0.45micron spin column.

Add: 0.54ul 10% SDS.

Incubate reaction at 100° C for 2 min.

Apply to prepared microarray.

Probe preparation by direct

Cy-dNTP incorporation

Preparing labeled cDNA from RNA for expression

studies may seem complicated but it is one of the simplest molecular

techniques. The major necessary

components, RNA, RT, and fluor-dNTP are relatively straightforward to use. Generally, RNA and a primer that will be

used to initiate reverse transcription are mixed, heated (to allow annealing),

and chilled. A cocktail of enzyme,

buffer, etc… is made for each of the fluors, and added to the RNA mixture. The RT reaction is allowed to proceed, until

the two probes are prepared to be mixed, when EDTA (and NaOH) is added to

prevent DNA production. The next key

step is that the unincorporated fluor needs to be removed by using a centricon

filter (which retains molecules with a certain MW or greater, 30 kD works

well). This purified cDNA is ready to

be used as a probe.

Reagents

RNA

Olgio dT 1.5 mg/ml (~18mer)

65 C heat block

42 C heat block

100 C heat block

0.1 M DTT

First strand buffer

Reverse transcriptase (Superscript II)

Labeling mix 25

mM dATP, 25 mM dCTP, 25 mM dGTP, 15 mM dTTP

Cy3-dUTP

Cy5-dUTP

Stop solution 1

N NaOH, 0.1 M EDTA

Neutralization solution 1 N HCl

Centricon-30

TE

Water

Directions

(1) Aliquot

15 ug of total yeast RNA or up to 2 ug of polyA+ RNA into each reaction tube

(0.5 ml or 1.5ml).

(2) Add

6 ug (for total) or 4 ug (for polyA+) olgio-dT.

(3) Heat

65 C, 1 min.

(4) Chill

on ice.

(5) Make

a master mixture of:

6

ul first strand buffer

3

ul 0.1 M DTT

0.6

ul labeling mix

3

ul Cy-dUTP

2

ul reverse transcriptase

for

each reaction.

(6) Add

14.5 ul of master mix to each RNA/oligo-dT sample.

(7) Incubate

at 42 C for two hours.

(8) Add

1.5 ul stop solution.

(9) Heat

10 min 65 C.

(10) Add

1.5 ul neutralization solution.

(11) Mix

differentially labeled sample in a centricon-30.

(12) Add

400 ul of TE.

(13) Centrifuge

9 min at 14,000g.

(14) Empty

flow through and add 500 ul water.

(15) Centrifuge

until 5-10 ul remains above the membrane

(16) Collect

labeled cDNA.

Notes

Several

different steps can be excluded or included from the protocol presented

here. Degradation of the RNA by adding

the stop solution is probably unnecessary, as is neutralizing the stop solution

directly. A vast excess of TE will do

the trick. One step that seems

important is to keep the reactions to 30 ul, changing the volume of the

reaction can affect the heating/cooling steps resulting in changes in the

representation of the cDNA produced or available for hybridization. Probes can usually be stored overnight in

the refrigerator.

Microarray hybridizations

Reagents

Labeled cDNA

20X SSC

10% SDS

2.5% SDS

20 mg/ml yeast tRNA

Microarray

Cover slips

Hybridization chambers

Water

Directions

(1) Add

2 ul of 20X SSC to labeled cDNA mixture

(2) Add

1 ul of tRNA.

(3) Add

1 ul of 2.5% SDS

(4) Bring

final mixture to 14 ul.

(5) Insert

microarray into chamber, placing 10 ul water at one end of the chamber.

(6) Pipet

cDNA mixture onto center of array.

(7) Place

a cover slip over the array, prevent bubble formation.

(8) Close

chamber, place in 65 C bath for 4-24 hrs.

(9) Remove

chamber from bath and array from

chamber.

(10) Carefully

place array into slide holder in 1X SSC, 0.2% SDS.

(11) Shake

slowly until cover slip falls off.

(12) Plunge

slide ~20 times, transfer to 0.4X SSC, plunge ~20 times, transfer to 0.2X SSC,

plunge ~20 times.

(13)

Spin

array dry in centrifuge at 600 rpm.

Notes

There are more tricks to this protocol than a dog

could ever learn. Everybody does it

differently and it doesn’t seem to make a substantial difference. Some of the interesting differences are…

(1)

cover

slips- glass, plastic, beveled edges…

(2)

hybridization

volume- 10, 12, 14, 20 ul or more.

(3)

Various

blocking agents (repetitive DNA, oligo dA…)

(4)

Cover

slip placement (dropping, tweezers…)